Metal Wall Panel & Siding Systems

-

![HWP]()

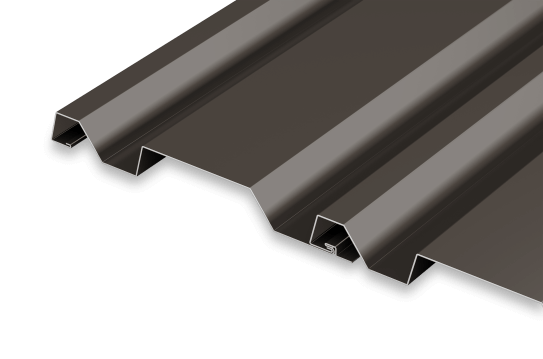

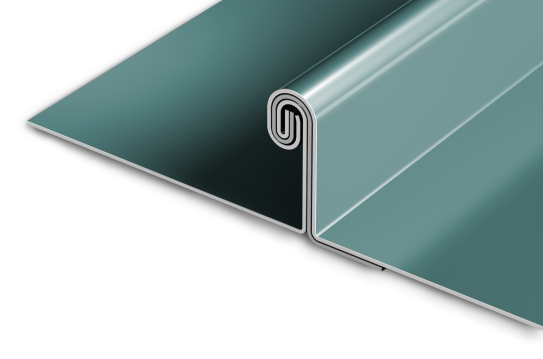

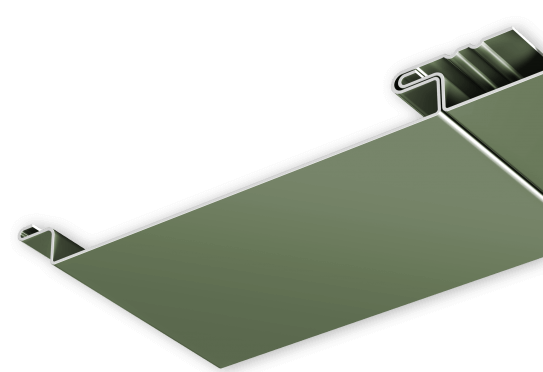

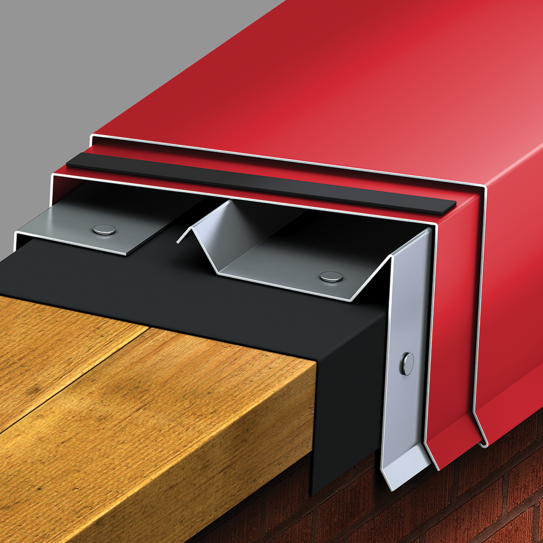

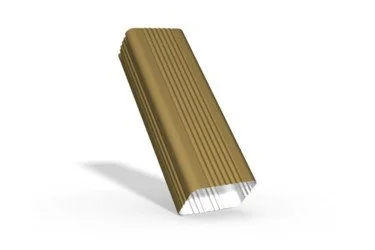

HWP

The Precision Series of architectural wall panels includes twelve profiles that provide architects and designers with creative flexibility by combining bold visual effects with easy, cost-effective installation. Multiple profiles are available with a variety of rib patterns in two depths. Each profile is offered in a no-clip (fastener flange) option, or a clip-fastened panel to accommodate thermal expansion and contraction. All Precision Series panels can connect to each other if desired.

These ribbed wall panels create attractive lines and shadows for the exterior of any building, nonresidential or residential. All twelve of the Precision Series panels can be mixed with each other to create custom patterns. The Precision Series lineup includes the original HWP profile (7/8-in. depth), seven Highline profiles (1 3/8-in depth) and four Box Rib options (1 3/8-in depth).

Consult Petersen rep for maximum length; minimum panel length is 4-ft. Note: Minimum length for panels produced in the Annapolis Junction, Md., facility is 60 inches. Additionally, these wall panels can be specified as perforated in aluminum only for use in equipment screen applications or over graphics. Petersen’s Box Rib panels are ideal for practically any structure that requires exterior wall cladding such as schools, hospitals, banks, sports facilities, office and industrial buildings, and most other nonresidential applications, but also residential buildings.

-

![Highline Wall Panel Systems]()

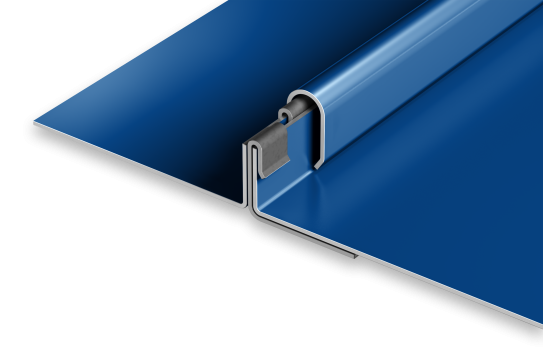

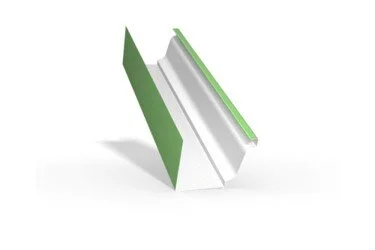

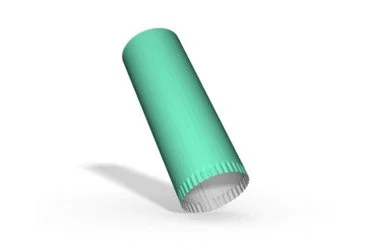

Highline Wall Panel Systems

The Precision Series of architectural wall panels includes twelve profiles that provide architects and designers with creative flexibility by combining bold visual effects with easy, cost-effective installation. Multiple profiles are available with a variety of rib patterns in two depths. Each profile is offered in a no-clip (fastener flange) option, or a clip-fastened panel to accommodate thermal expansion and contraction. All Precision Series panels can connect to each other if desired.

These ribbed wall panels create attractive lines and shadows for the exterior of any building, nonresidential or residential. All twelve of the Precision Series panels can be mixed with each other to create custom patterns. The Precision Series lineup includes the original HWP profile (7/8-in. depth), seven Highline profiles (1 3/8-in depth) and four Box Rib options (1 3/8-in depth).

Consult Petersen rep for maximum length; minimum panel length is 4-ft. Note: Minimum length for panels produced in the Annapolis Junction, Md., facility is 60 inches. Additionally, these wall panels can be specified as perforated in aluminum only for use in equipment screen applications or over graphics. Petersen’s Box Rib panels are ideal for practically any structure that requires exterior wall cladding such as schools, hospitals, banks, sports facilities, office and industrial buildings, and most other nonresidential applications, but also residential buildings.

-

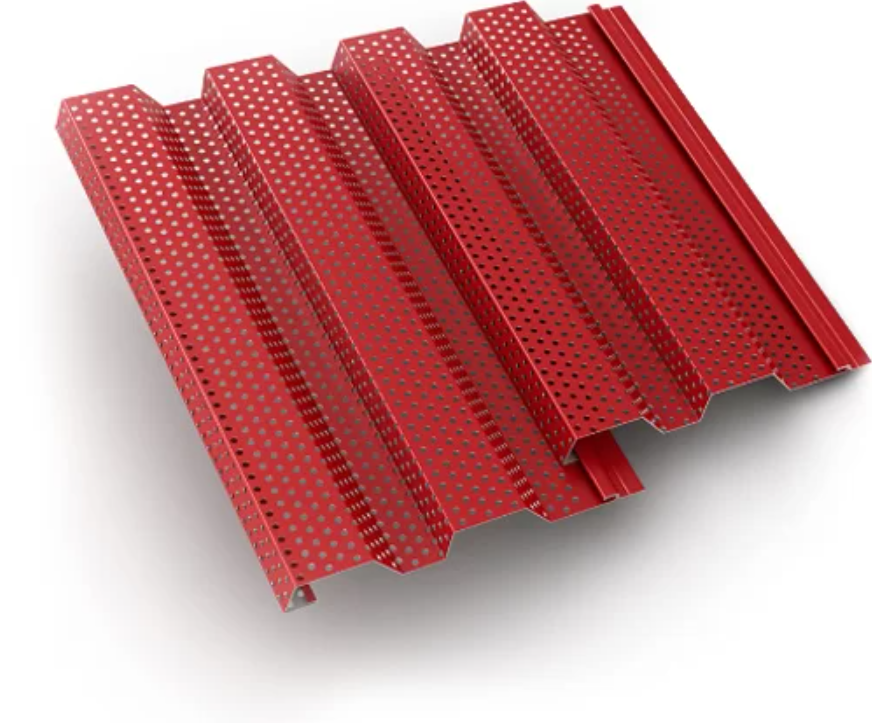

![Box Rib Wall Panel Systems]()

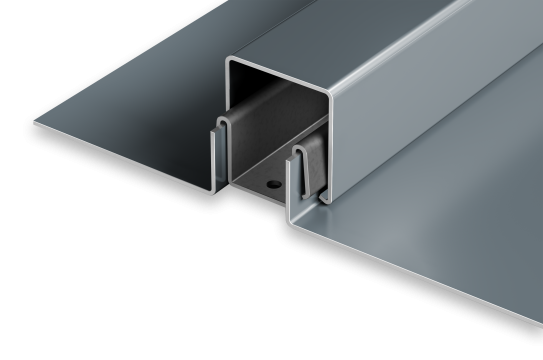

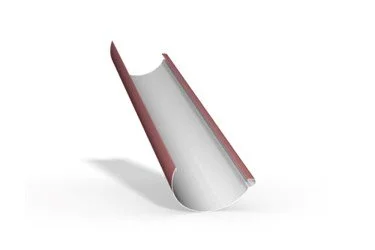

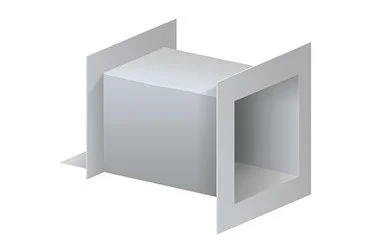

Box Rib Wall Panel Systems

Precision Series Box Rib architectural wall panels provide design flexibility by combining bold visual effects with easy, cost-effective installation. Multiple profiles are available with a variety of rib patterns. Each profile is offered in a no-clip panel, or a clip-fastened panel to accommodate expansion and contraction.

The Box Rib profiles are 1-3/8” deep and a nominal 12” wide. All precision Series profiles, including Box Rib, Highline and HWP, can be intermixed to add visual intensity to a building’s exterior. Precision Series wall panels can be installed horizontally or vertically. Consult Petersen rep for maximum length; minimum panel length is 4’.

Additionally, Precision Series wall panels can be specified as perforated but only in aluminum for use in equipment screen applications, over graphics or for architectural flair.

Box Rib panels should be installed in single-piece runs, either horizontally or vertically. For panels more than 20-ft. long, the clip version should be utilized. For panels less than 20-ft. long, the screw leg version is acceptable. For wall elevations with panels longer than 36-ft., flashing breaks must be used as indicated by the architect or designer. Box Rib panels are NOT designed to be field-lapped over one another.

Consult Petersen rep for maximum length; minimum panel length is 4-ft. Note: Minimum length for panels produced in the Annapolis Junction, Md., facility is 60 inches.

-

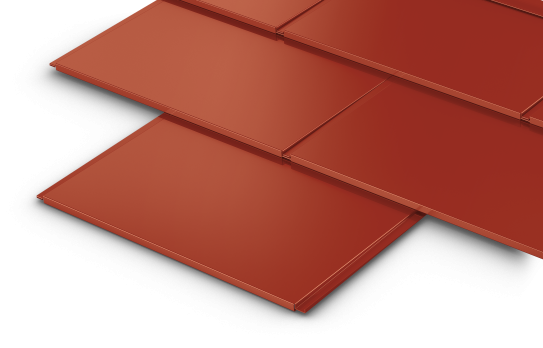

![Flush & Reveal Wall Panels]()

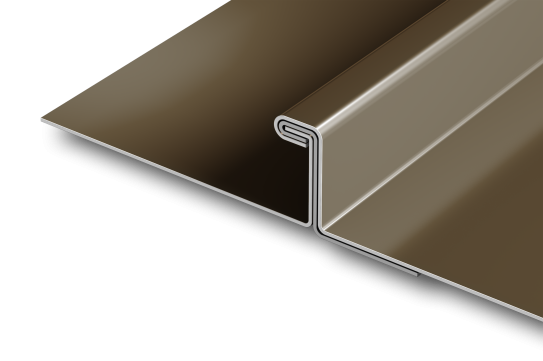

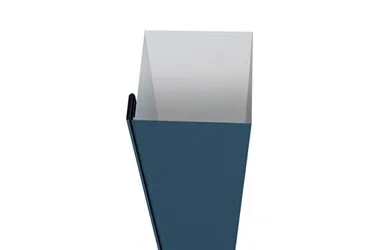

Flush & Reveal Wall Panels

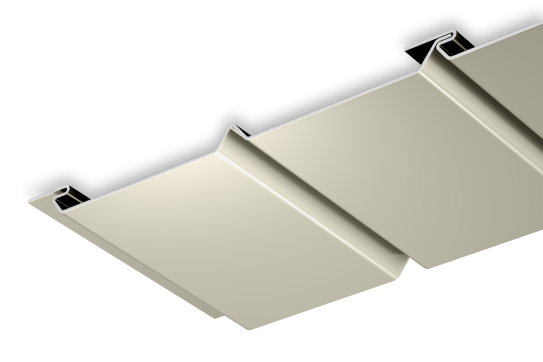

Flush panels are designed for wall, fascia and soffit applications where a flush or flat appearance is desired. A rounded interlock leg and concealed fastening system improves the flush appearance while providing additional strength. Panels are factory-formed to length to minimize field cutting. Maximum panel length is 25’ and minimum panel length is 4’.

Flush panels are available in on-center dimensions designed to complement Petersen’s roofing panel product line. Flush panels are available in Flush and Reveal joint configurations.

-

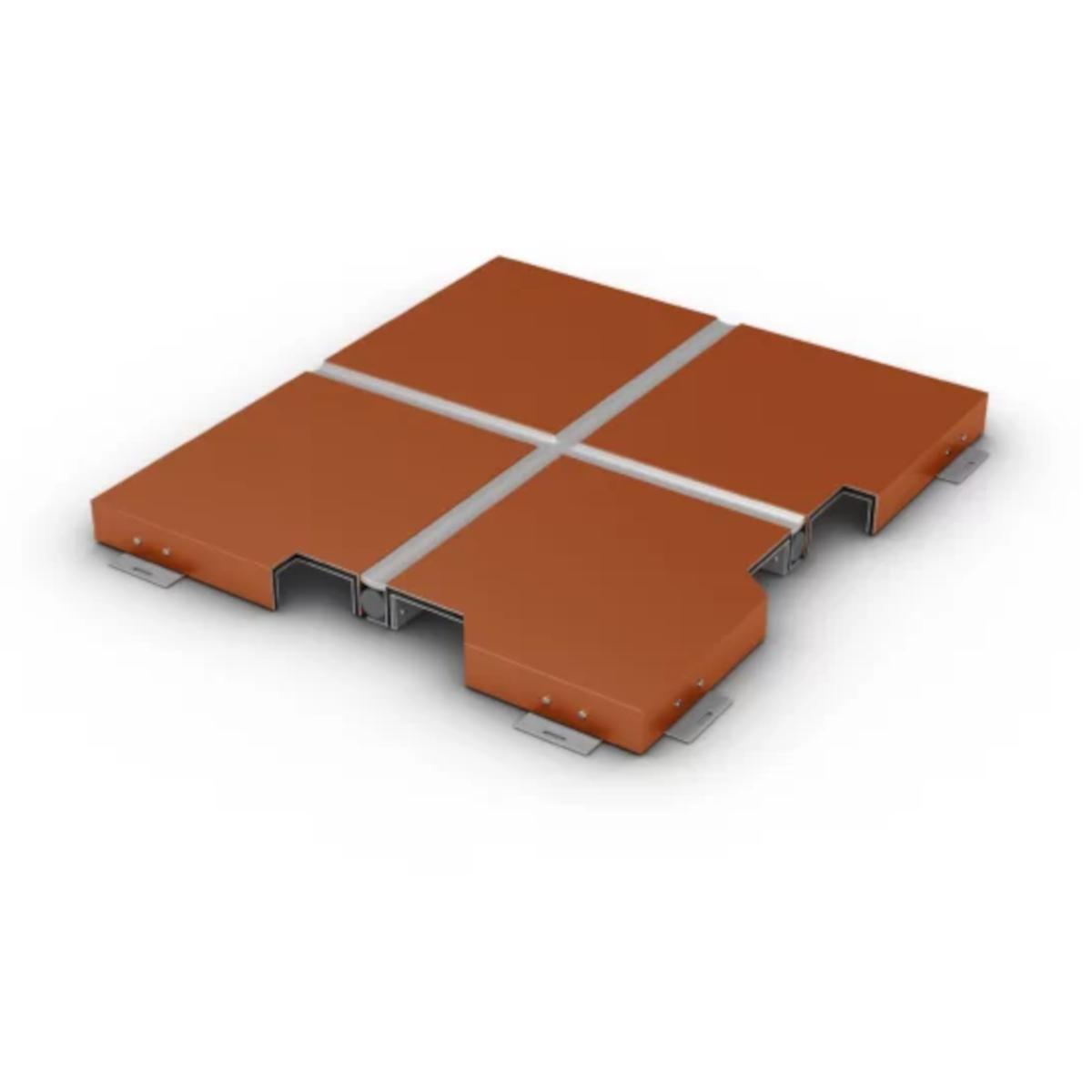

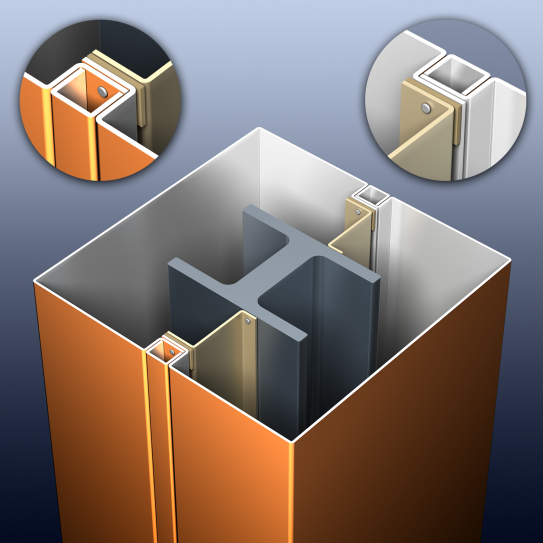

![Composite Wall Panels]()

Composite Wall Panels

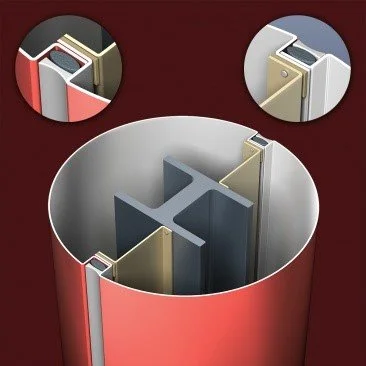

Petersen offers another dimension in design flexibility with its series of composite wall panels. PAC’s panel systems provide unmatched performance and stunning visual effects for any commercial or retail application.

The PAC-3000 CS panels are comprised of an .020 face and back skin thermobonded to a polyethylene or fire-retardant core. Panels are formed by a rout-and-return process utilizing computer-controlled routing equipment. This state-of-the-art fabrication ensures tight tolerances and accurate panel dimensions. Staggered angle clips mounted to the panel allow for each panel to be installed and adjusted individually.

The PAC-3000 RS is a rain-screen system that eliminates the use of caulk, utilizing clean reveals for an architecturally pleasing system. The system is constructed with metal composite material (MCM), available in a wide range of finishes and colors to complement any design scheme. Extrusions are fixed to the perimeter of the panel and nest into the extruded track which is attached to the substrate. The result is a free-floating panel installation since the panel is not fastened to the substrate.

Exposed Fastener Panels

-

![M-42 & M-36 Panels]()

M-42 & M-36 Panels

Petersen offers a complete line of exposed fastener panels, allowing for creative design flexibility in a cost-effective yet architecturally attractive metal panel. The versatile 7.2 panel, R-36 and 7/8” Corrugated panels can be specified for a wide range of building envelope applications including roofs, walls and linear panels. The M-36, M-42 and 1/2” Corrugated panels are suitable for wall and equipment screen projects.

-

![7.2 Panel]()

7.2 Panel

Petersen offers a complete line of exposed fastener panels, allowing for creative design flexibility in a cost-effective yet architecturally attractive metal panel. The versatile 7.2 panel, R-36 and 7/8” Corrugated panels can be specified for a wide range of building envelope applications including roofs, walls and linear panels. The M-36, M-42 and 1/2” Corrugated panels are suitable for wall and equipment screen projects.

-

![1/2″ & 7/8″ Corrugated]()

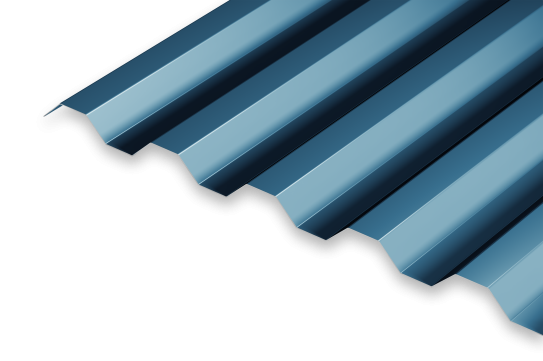

1/2″ & 7/8″ Corrugated

Petersen offers a complete line of exposed fastener panels, allowing for creative design flexibility in a cost-effective yet architecturally attractive metal panel. The versatile 7.2 panel, R-36 and 7/8” Corrugated panels can be specified for a wide range of building envelope applications including roofs, walls and linear panels. The M-36, M-42 and 1/2” Corrugated panels are suitable for wall and equipment screen projects.

-

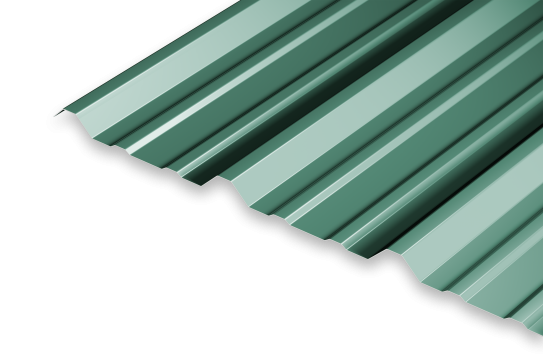

![R-36]()

R-36

Petersen offers a complete line of exposed fastener panels, allowing for creative design flexibility in a cost-effective yet architecturally attractive metal panel. The versatile 7.2 panel, R-36 and 7/8” Corrugated panels can be specified for a wide range of building envelope applications including roofs, walls and linear panels. The M-36, M-42 and 1/2” Corrugated panels are suitable for wall and equipment screen projects.

Metal Roofing Panels

-

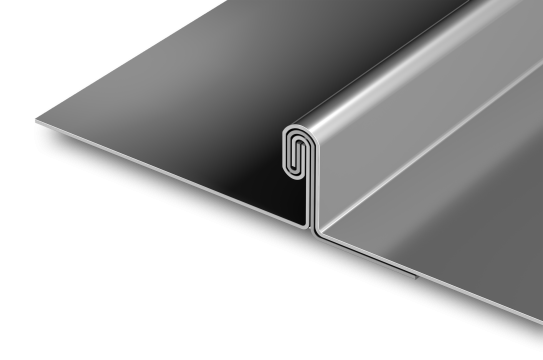

![Snap-Clad]()

Snap-Clad

Snap-Clad metal roofing panels feature architectural aesthetics as well as structural performance. Snap-Clad panels, produced in continuous lengths, are leveled to provide superior flatness and feature an optional factory-applied sealant bead for improved weather resistance. Maximum panel length is 64’ and minimum panel length is 4‘. Consult factory for longer lengths. Note: Minimum length for panels produced in the Annapolis Junction, Md., facility is 60 inches.

Each metal roofing panel features a 1-3/4” leg height and a continuous interlock for improved structural performance and wind resistance. A concealed-fastener clip system allows for thermal expansion/contraction while providing extraordinary hold-down strength. Two clips are available: a standard clip for most mansard and fascia applications, and a high-performance clip for roofing applications and UL 90-rated assemblies.

-

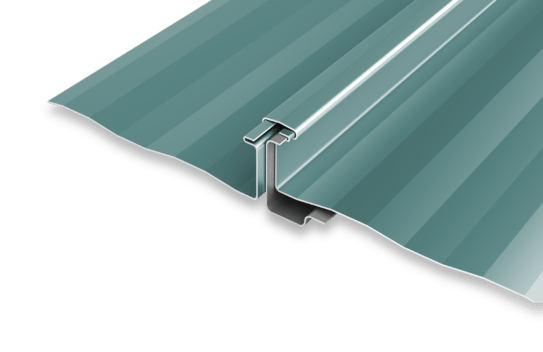

![Tite-Loc]()

Tite-Loc

Tite-Loc panels combine structural panel performance with architectural panel aesthetics. Tite-Loc panels are leveled to provide superior panel flatness. A factory-applied sealant bead can be applied for additional weather resistance. Maximum panel length is 64’ and minimum panel length is 4’. Consult factory for longer lengths. Note: Minimum length for panels produced in the Annapolis Junction, Md., facility is 60 inches.

Tite-Loc panels feature a 2” leg height that requires mechanical field seaming after installation. Panels have a concealed-fastener floating clip system designed to allow for thermal expansion/contraction.

-

![1/2″ & 7/8″ Corrugated]()

1/2″ & 7/8″ Corrugated

Tite-Loc Plus panels combine structural panel performance with architectural panel aesthetics. Tite-Loc Plus panels are leveled to provide superior panel flatness. A factory-applied sealant bead can be applied for additional weather resistance. Maximum panel length is 64’ and minimum panel length is 4’. Consult factory for longer lengths. Note: Minimum length for panels produced in the Annapolis Junction, Md., facility is 60 inches.

Tite-Loc Plus panels feature a 2” leg height that requires mechanical field seaming after installation. Panels have a concealed-fastener floating clip system designed to allow for thermal expansion/contraction.

-

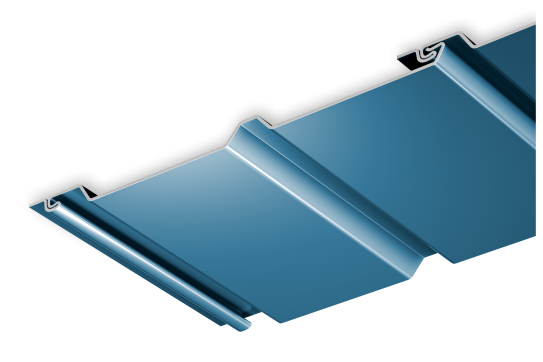

![Snap-On Standing Seam]()

Snap-On Standing Seam

Snap-On panels are ideal for use in roofing, mansard and fascia applications. Snap-On panels are designed to be installed over a waterproofed solid substrate and a minimum 3:12 roof pitch. Snap-On panels are factory roll-formed in continuous lengths. Maximum panel length is 35’ and minimum panel length is 4’. Consult factory for nonstandard lengths.

The simplicity of the pan design combined with leveling provides superior flatness and allows for greater workability on site.

-

![High Snap-On Standing Seam Panel]()

High Snap-On Standing Seam Panel

Snap-On panels are ideal for use in roofing, mansard and fascia applications. Snap-On panels are designed to be installed over a waterproofed solid substrate and a minimum 3:12 roof pitch. Snap-On panels are factory roll-formed in continuous lengths. Maximum panel length is 35’ and minimum panel length is 4’. Consult factory for nonstandard lengths.

The simplicity of the pan design combined with leveling provides superior flatness and allows for greater workability on site.

-

![Snap-On Batten]()

Snap-On Batten

Snap-On panels are ideal for use in roofing, mansard and fascia applications. Snap-On panels are designed to be installed over a waterproofed solid substrate and a minimum 3:12 roof pitch. Snap-On panels are factory roll-formed in continuous lengths. Maximum panel length is 35’ and minimum panel length is 4’. Consult factory for nonstandard lengths.

The simplicity of the pan design combined with leveling provides superior flatness and allows for greater workability on site.

-

![Redi-Roof Standing Seam]()

Redi-Roof Standing Seam

Redi-Roof standing seam is intended for application over a solid substrate with a minimum 3:12 standing seam roof pitch. Typical substrates include plywood, nailboard insulation or equal. Panels are factory roll-formed in continuous lengths. Maximum panel length is 45’ and minimum panel length is 4’.

Redi-Roof panels feature an offset profile which adds strength and allows room for a hex head fastener. The clip, with its button-punched design, ensures an extra-snug fit. The one-piece design allows for ease of installation.

-

![PAC-150 90° Single Lock]()

PAC-150 90° Single Lock

PAC-150 standing seam metal roofing panels combine semi-structural metal panel performance with architectural roofing panel aesthetics. PAC-150 roofing coil for field-forming operations is leveled to provide superior panel flatness. Maximum panel length is limited when factory or shop-formed but virtually unlimited when field-formed; minimum panel length is approximately 4’.

PAC-150 roofing panels feature a 1.5” leg height which requires mechanical field seaming to either 90° or 180° depending on the project’s uplift requirements. Panels have a concealed-fastener clip designed to allow for maximum design flexibility. For further details, please contact a Petersen rep.

This panel combines an attractive thin-rib profile with superior structural performance. PAC-150 panels are designed for application over a wide variety of substrates in slopes as low as 1:12 pitch. PAC-150 roofing panels are available in a wide variety of widths from 12” to 20”. Materials available include 24 gauge steel plus .032 aluminum.

-

![PAC-150 180° Double Lock]()

PAC-150 180° Double Lock

PAC-150 standing seam metal roofing panels combine semi-structural metal panel performance with architectural roofing panel aesthetics. PAC-150 roofing coil for field-forming operations is leveled to provide superior panel flatness. Maximum panel length is limited when factory or shop-formed but virtually unlimited when field-formed; minimum panel length is approximately 4’.

PAC-150 roofing panels feature a 1.5” leg height which requires mechanical field seaming to either 90° or 180° depending on the project’s uplift requirements. Panels have a concealed-fastener clip designed to allow for maximum design flexibility. For further details, please contact a Petersen rep.

This panel combines an attractive thin-rib profile with superior structural performance. PAC-150 panels are designed for application over a wide variety of substrates in slopes as low as 1:12 pitch. PAC-150 roofing panels are available in a wide variety of widths from 12” to 20”. Materials available include 24 gauge steel plus .032 aluminum.

-

![PAC T-250]()

PAC T-250

PAC T-250 metal roof panels are factory-formed or field-formed to length and field-seamed. The panels have been designed for application over a wide variety of substrates on roof slopes as low as 1/2 : 12. PAC T-250 panels can be produced in 22 and 24 gauge steel or .032 and .040 aluminum. The PAC T-250 panel combines structural performance with architectural aesthetics. PAC T-250 panels feature a 2.625” nominal finished panel height from the deck that requires mechanical field seaming after installation. The panels have a continuous and/or intermittent concealed-fastener clip system designed to allow for thermal expansion/contraction. Sealant beads are factory-applied to the seam cover.

Soffit Panel Systems

-

![PAC-750 Soffit]()

PAC-750 Soffit

Petersen offers superior design versatility for soffit applications by providing the PAC-750/850 aluminum Soffit panels, as well as the Flush panel in a variety of gauges and widths. Both pre-formed profiles are effective solutions in soffit projects, and with the aluminum substrate can be ventilated for increased airflow capacity.

-

![PAC-850 Soffit]()

PAC-850 Soffit

Petersen offers superior design versatility for soffit applications by providing the PAC-750/850 Soffit panels, as well as the Flush panel in a variety of gauges and widths. Both pre-formed profiles are effective solutions in soffit projects, and with the aluminum substrate can be ventilated for increased airflow capacity.

-

![Flush/Reveal Soffit]()

Flush/Reveal Soffit

Petersen offers superior design versatility for soffit applications by providing the PAC-750/850 Soffit panels, as well as the Flush panel in a variety of gauges and widths. Both pre-formed profiles are effective solutions in soffit projects, and with the aluminum substrate can be ventilated for increased airflow capacity.

Perforated Aluminum

-

![Perf Aluminum]()

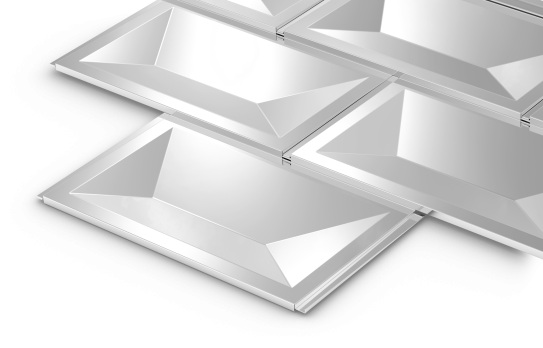

Perforated Aluminum

Petersen offers perforation of select PAC-CLAD aluminum wall panels and flat sheet. Perforated aluminum can provide a contrasting look with any non-perforated metal to create visual interest on any project. Architects can specify perforated aluminum to diffuse light, air or sound, or simply for architectural flair. Typical applications include equipment screens, partitions, sign panels, parking decks, guards, interior acoustical applications and enclosures of any kind.

Perforated metal is available in a nearly endless combination of hole sizes, spacing and open space percentages to complement virtually any architectural design or need. Perforation options will vary by panel profile and aluminum thickness; consult factory for details.

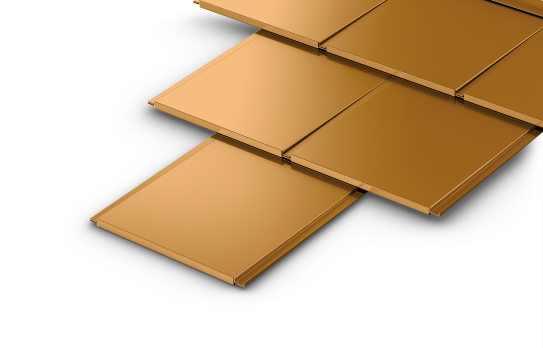

Precision Series Tile

-

![PAC-750 Soffit]()

Cupped Tile

The cupped tile catches light at multiple angles that creates a multi-shade effect as viewing perspective changes. In roof applications, installers can safely walk on the cupped tiles during installation.

-

![PAC-850 Soffit]()

Flat Tile

The flat tile has the flexibility to integrate with both modern and traditional designs.

-

![Flush/Reveal Soffit]()

Diamond Tile

Diamond tiles can be installed horizontally, or on an angle to achieve a diamond or clapboard pattern.

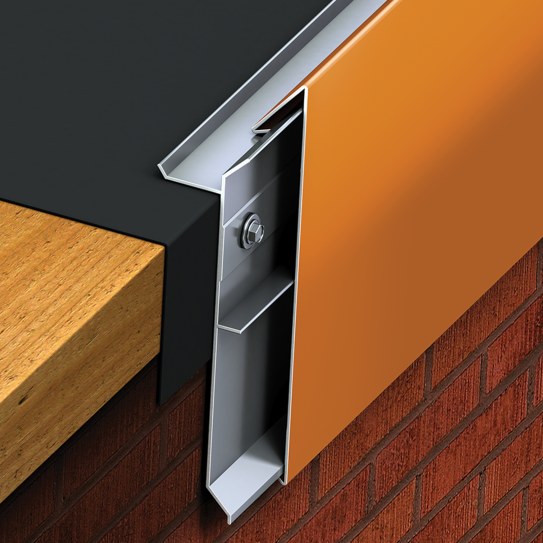

Metal Roofing Fascia Systems

-

![PAC-750 Soffit]()

PAC-TITE Angular Fascia: Angular Fascia FA

PAC-TITE Angular Fascia provides unmatched uplift protection for single-ply and built up/modified roof systems. Combining superior strength and aesthetics with ease of installation, PAC-TITE Angular Fascia offers the ideal solution in roof edge applications, meeting the most stringent performance requirements. A non-penetrating design eliminates the need for stripping in and heat welding, maintaining the watertight integrity of the installation. PAC-TITE Angular Fascia features an extruded aluminum anchor bar to securely terminate the membrane. The bar is readily available to dry-in the roof structure for added installation flexibility.

-

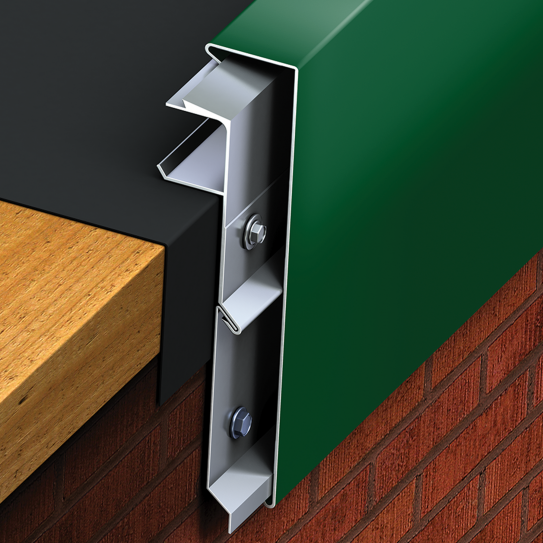

![PAC-850 Soffit]()

PAC-TITE WT Canted Fascia: WT Canted Fascia - Waterdam

PAC-TITE WT Canted Fascia with Galvanized Waterdam features a unique design that keeps the flange out of the waterline. It is available in two profiles, both in .050 and .063 aluminum fascia covers: The standard Canted Fascia version is available in a 5 1/2″ face. The PAC-TITE WT Extended Canted Fascia profile is offered in 9″ to 13 1/2″ face heights to accommodate multiple nailers without the need for a fascia extender. A non-penetrating design eliminates the need for stripping in and heat welding. The fascia features an extruded aluminum anchor bar to securely terminate the membrane, and is readily available for quick shipment to dry-in the roof structure for added installation flexibility.

-

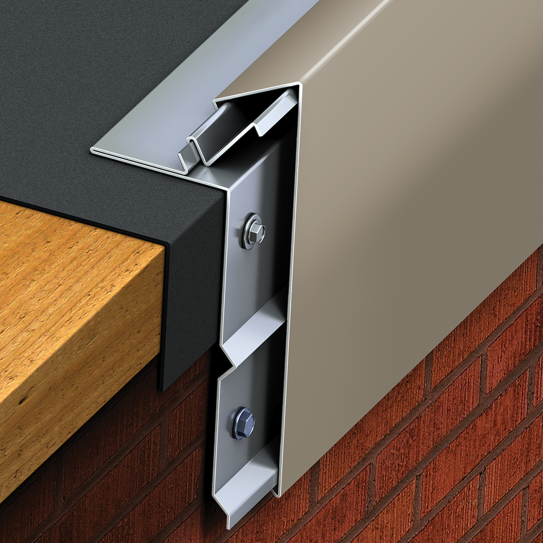

![Flush/Reveal Soffit]()

PAC-TITE WT Fascia: WT Fascia FA

PAC-TITE WT Fascia has been specifically designed to meet architectural and industry demands to allow for the smaller face height in heavier gauge covers, such as .050 and .063 aluminum. A non-penetrating design eliminates the need for stripping in and heat welding, maintaining the watertight integrity of the installation. PAC-TITE WT Fascia features an extruded aluminum anchor bar to securely terminate the membrane. The bar is readily available to dry-in the roof structure for added installation flexibility.

-

![]()

PAC-TITE WT Extended Fascia: WT Ext Fascia FA

PAC-TITE WT Extended Fascia is available in face heights up to 13” and in .050 and .063 aluminum. This eliminates the need for fascia extenders for substantial time and labor savings. A non-penetrating design eliminates the need for stripping in and heat welding. The possibility of improper flashing procedures or failed adhesives or sealants will not impact the ability of PAC-TITE WT Extended fascia to maintain the watertight integrity of the installation. The fascia features an extruded aluminum anchor bar to securely terminate the membrane, and is readily available for quick shipment to dry-in the roof structure for added installation flexibility.

-

![]()

PAC-LOC Fascia: PAC-LOC Fascia 2000

PAC-LOC Fascia Systems combine a clean and elegant design, competitive pricing and ease of installation to provide unmatched uplift protection for single-ply and built up/modified roof systems. Available in a wide range of gauges and face sizes, PAC-LOC Fascia offers superior design flexibility to fulfill the demanding requirements for a variety of roof edge conditions.

-

![]()

PAC Snap Edge Fascia: PAC Snap Edge FA

With PAC Snap Edge Fascia, outstanding protection against wind up-lift damage for flat roof installations meets superior economy and ease of installation. PAC Snap Edge is the ideal solution for keeping roof edge projects on schedule and on budget while meeting the rigorous standards of ANSI/SPRI ES-1 standards. Installation is fast and easy, featuring a snap-on cover to eliminate field crimping, and an efficient design that does not require stripping in or heat welding. The product is produced in 12′ lengths for an estimated 20% – 40% savings in material handling over the typical 8′ and 10′ lengths.

-

![]()

PAC Snap Edge Extended Fascia: PAC Snap Edge Extended BUM

With PAC Snap Edge Extended Fascia, outstanding protection against wind up-lift damage for flat roof installations meets superior economy and ease of installation. PAC Snap Edge Extended Fascia is the ideal solution for keeping roof edge projects on schedule and on budget while meeting the rigorous standards of ANSI/SPRI ES-1 standards. Available in face heights up to 12 1/2″, the extended profile allows for extra coverage over multiple nailers while eliminating the use of extenders. Installation is fast and easy, featuring a snap-on cover to eliminate field crimping, and an efficient non-penetrating design that does not require stripping in or heat welding. The product is produced in 12′ lengths for an estimated 20% – 40% savings in material handling over the typical 8′ and 10′ lengths.

Coping Systems

-

![PAC-750 Soffit]()

PAC-TITE Gold Coping

The PAC-TITE Gold coping system provides premium wind uplift protection in parapet wall covering applications, and is ideal for conditions in which slope must be created. The high-performing system features factory-applied stainless steel springs ensuring a long-term, positive attachment for extra stability for the roof system. PAC-TITE Gold coping provides specifiers and contractors unmatched strength, beauty, ease of installation and ability to meet rigorous testing requirements in perimeter applications. The superior engineering of PAC-TITE Gold coping ensures an aesthetically pleasing, high performance installation. The system can meet unique design requirements including radius, arched and elliptical conditions. PAC-TITE Gold coping offers unlimited flexibility, accommodating inside face dimensions of 2.75” to 6”, and outside face dimensions of 3” to 12”. PAC-TITE Gold coping can be custom fabricated to meet wider wall widths of over 16”, and has been tested on wall widths up to 32”. Fabricated from high quality PAC-CLAD steel and aluminum, PAC-TITE Gold can be specified in a wide range of standard/stocked colors to complement any exterior design scheme. The system is backed by a Lifetime, 215 mph wind warranty. Offering a wide range of factory-fabricated accessories such as quicklocked or welded miters, Petersen provides the complete system to ensure a clean, sure-fitting product while eliminating the need for field fabrication.

-

![PAC-850 Soffit]()

PAC-TITE Coping: Tapered

The PAC-TITE Coping system is the complete package, providing specifiers and contractors unmatched strength, beauty, ease of installation and ability to meet rigorous testing requirements in perimeter applications. PAC-TITE Coping also offers design flexibility, capable of accommodating wall widths up to 32″. The superior engineering of PAC-TITE coping ensures an aesthetically pleasing, high performance installation. Concealed, 8″ wide splice plates include sealant strips to produce a watertight seal at the joints while allowing for proper thermal movement. Galvanized steel anchor clips have pre-punched holes for proper attachment to the building substrate. Factory applied, corrosion resistant stainless steel springs provides long-term positive attachment. Yet, the easily installed snap-on design of the cover, in a wide range of architectural finishes, ensures beauty for a long time to come.

-

![Flush/Reveal Soffit]()

PAC-Continuous Cleat Coping

The innovative design of PAC-CLAD Continuous Cleat Coping permits the installation of a sloped coping cap over extra wide walls. The support of the cleat substantially reduces sagging, which can induce ponding and the possibility of leaks. For further weather tightness, neoprene strips are factory applied to each hold down cleat (see illustration). Factory-supplied fasteners accompany each coping order to assure proper attachment of the cleats to the wood nailer. Field-crimping on the inside leg of the coping to the inside hold down cleat completes the installation.

Gutter and Downspout Systems

-

![PAC-750 Soffit]()

PAC-TITE Gold Gutters: IGG-1

Superior Roof Drainage with GT-1 Testing. PAC-Tite Gold Gutters are top-of-the-line, offering easy installation, outstanding performance and an attractive appearance. They include a 2” wide external wind strap to be installed every 6’ and gutter straps every 24” O.C. to comply with the ANSI/SPRI GT-1 Standard. They also feature a unique, heavy aluminum gutter strap design that eliminates the need for drilling and riveting. The free-floating, hook-in strap allows for full thermal movement of the gutter. Offered with an optional roof flange or slotted drain bars for ballast retention, PAC-Tite Gold Gutters offer maximum roof drainage.and application time in half with this one-of-a-kind edge metal solution.

-

![PAC-850 Soffit]()

PAC-TITE Gold Gutters: IGG-2

Superior Roof Drainage with GT-1 Testing. PAC-Tite Gold Gutters are top-of-the-line, offering easy installation, outstanding performance and an attractive appearance. They include a 2” wide external wind strap to be installed every 6’ and gutter straps every 24” O.C. to comply with the ANSI/SPRI GT-1 Standard. They also feature a unique, heavy aluminum gutter strap design that eliminates the need for drilling and riveting. The free-floating, hook-in strap allows for full thermal movement of the gutter. Offered with an optional roof flange or slotted drain bars for ballast retention, PAC-Tite Gold Gutters offer maximum roof drainage.and application time in half with this one-of-a-kind edge metal solution.

-

![Flush/Reveal Soffit]()

PAC-TITE Gold Gutters: IGG-3

Superior Roof Drainage with GT-1 Testing. PAC-Tite Gold Gutters are top-of-the-line, offering easy installation, outstanding performance and an attractive appearance. They include a 2” wide external wind strap to be installed every 6’ and gutter straps every 24” O.C. to comply with the ANSI/SPRI GT-1 Standard. They also feature a unique, heavy aluminum gutter strap design that eliminates the need for drilling and riveting. The free-floating, hook-in strap allows for full thermal movement of the gutter. Offered with an optional roof flange or slotted drain bars for ballast retention, PAC-Tite Gold Gutters offer maximum roof drainage.and application time in half with this one-of-a-kind edge metal solution.

-

![]()

PAC-TITE Gold Gutters: IGG-B

Superior Roof Drainage with GT-1 Testing. PAC-Tite Gold Gutters are top-of-the-line, offering easy installation, outstanding performance and an attractive appearance. They include a 2” wide external wind strap to be installed every 6’ and gutter straps every 24” O.C. to comply with the ANSI/SPRI GT-1 Standard. They also feature a unique, heavy aluminum gutter strap design that eliminates the need for drilling and riveting. The free-floating, hook-in strap allows for full thermal movement of the gutter. Offered with an optional roof flange or slotted drain bars for ballast retention, PAC-Tite Gold Gutters offer maximum roof drainage.and application time in half with this one-of-a-kind edge metal solution.

-

![]()

PAC-TITE LT Gutter: K-Style

The unique design, maximum roof drainage, and attractive appearance make PAC-Tite LT Gutters stand out from the crowd.

-

![]()

PAC-TITE LT Gutter: Half Round

The unique design, maximum roof drainage, and attractive appearance make PAC-Tite LT Gutters stand out from the crowd.

-

![]()

Industrial Downspout: Closed

The Industrial Downspout is available in a variety of standard sizes, or it can be fabricated to meet specific job requirements. Downspouts are manufactured with simple connection configurations and include three attachment straps per 12’ section, which enables fast and easy installation.

-

![]()

Industrial Downspout: Open

The Industrial Downspout is available in a variety of standard sizes, or it can be fabricated to meet specific job requirements. Downspouts are manufactured with simple connection configurations and include three attachment straps per 12’ section, which enables fast and easy installation.

-

![]()

PAC-TITE LT Downspout: Corrugated

Our PAC-Tite LT Industrial Gutter System not only weathers the storm, it does so in style with it’s superior performance and attractive appearance. That’s why PAC-Tite LT Corrugated Downspouts stand out from the crowd.

-

![]()

PAC-TITE LT Downspout: Round

Our PAC-Tite LT Industrial Gutter System not only weathers the storm, it does so in style with it’s superior performance and attractive appearance. That’s why PAC-Tite LT Corrugated Downspouts stand out from the crowd.

-

![]()

Thru-Wall Scupper

Check out the variety of custom-designed Scuppers and Collector Boxes that meet the performance requirements of architects and contractors. Their unique design provides maximum security and performance to protect against leaks and is a decorative and functional means of water control.

-

![]()

Thru-Wall Collection Box

Check out the variety of custom-designed Scuppers and Collector Boxes that meet the performance requirements of architects and contractors. Their unique design provides maximum security and performance to protect against leaks and is a decorative and functional means of water control.

Metal Column Covers

-

![PAC-750 Soffit]()

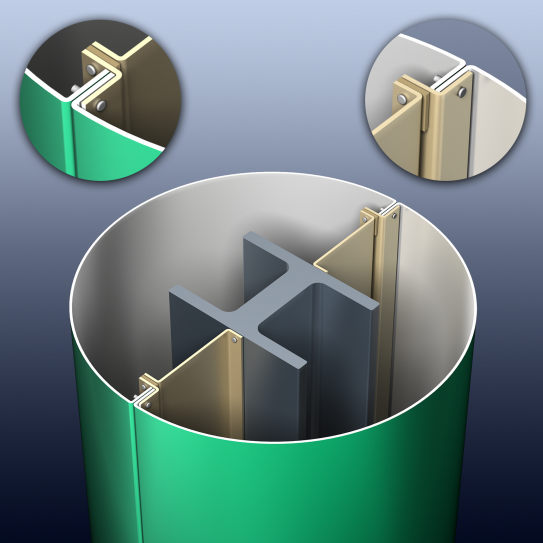

PAC-1000C Column Cover

The PAC-1000C Caulk Joint column cover is designed to leave a small open vertical reveal where the sections meet. Backer rod and caulk are applied to the vertical reveal joint to complete the installation. The PAC-1000C round column covers can be fabricated to various diameters. Please contact Petersen for complete details regarding our fabrication flexibility and capabilities.

-

![PAC-850 Soffit]()

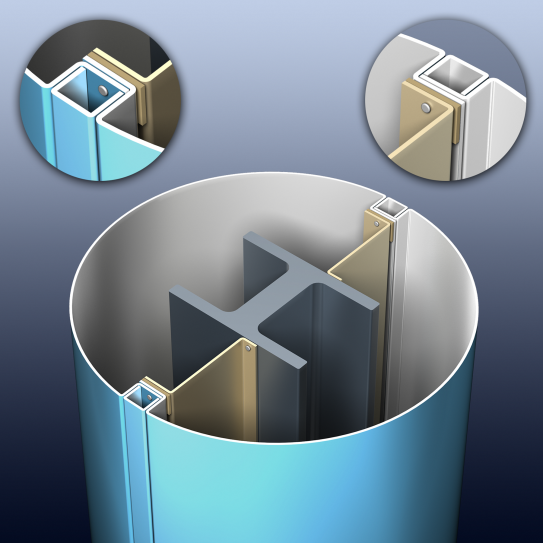

PAC-1000F Column Cover

The design of the PAC-1000F Flush Joint column covers allows for a clean, precise installation, revealing only a hairline joint. The column sections are assembled using a rivnut/keyhole system to provide a tight inconspicuous vertical seam. The PAC-1000F round column covers can be fabricated to various diameters. Please contact Petersen for complete details regarding our fabrication flexibility and capabilities.

-

![Flush/Reveal Soffit]()

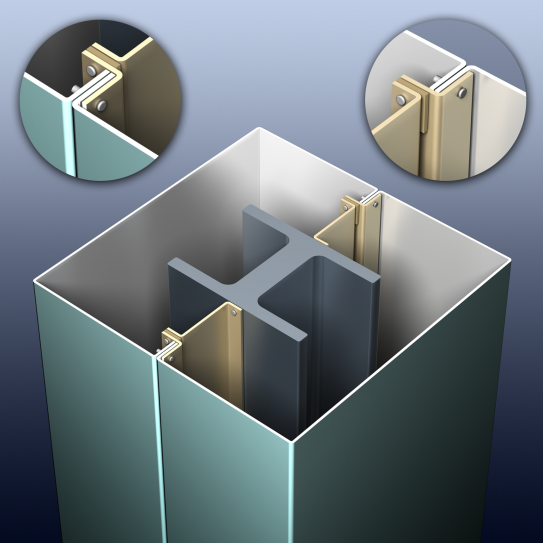

PAC-1000R Column Cover

The PAC-1000R Reveal Joint column cover is designed to leave a small open vertical reveal where the sections meet. A metal channel filler is fabricated to fit into the vertical joint and is set in sealant for a clean, easy installation. The PAC-1000R round column covers can be fabricated to various diameters. Please contact Petersen for complete details regarding our fabrication flexibility and capabilities.

-

![]()

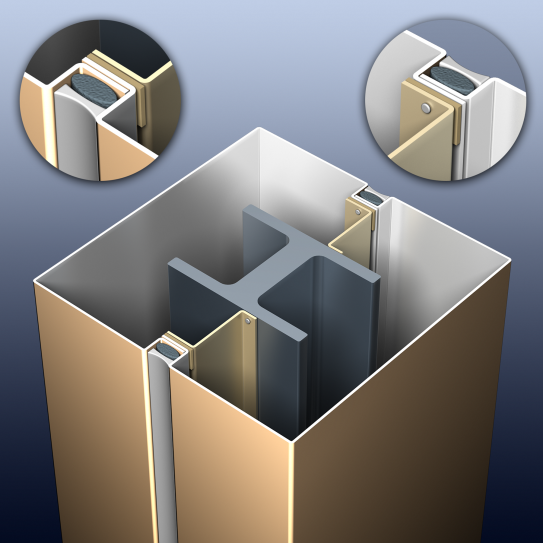

PAC-2000C Column Cover

The PAC 2000C Caulk Joint column cover is designed to leave a small open vertical reveal where the sections meet. Backer rod and caulk are applied to the vertical reveal joint to complete the installation. The PAC 2000C square column covers can be fabricated to various widths. Please contact Petersen for complete details regarding our fabrication flexibility and capabilities.

-

![]()

PAC-2000F Column Cover

The design of the PAC-2000F Flush Joint column covers allows for a clean, precise installation, revealing only a hairline joint. The column sections are assembled using a rivnut/keyhole system to provide a tight inconspicuous vertical seam. The PAC-2000F square column covers can be fabricated to various widths. Please contact Petersen for complete details regarding our fabrication flexibility and capabilities.

-

![]()

PAC-2000R Column Cover

The PAC-2000R Reveal Joint column cover is designed to leave a small open vertical reveal where the sections meet. A metal channel filler is fabricated to fit into the vertical joint and is set in sealant for a clean, easy installation. The PAC-2000R square column covers can be fabricated to various widths. Please contact Petersen for complete details regarding our fabrication flexibility and capabilities.

Insulation / Underlayment

-

![PAC-750 Soffit]()

PAC-CLAD HT

PAC-CLAD HT from Petersen is a self-adhering, high-temperature roofing underlayment designed to provide premium waterproofing protection for a variety of roofing applications. PAC-CLAD HT underlayment offers protection against water and ice damming while withstanding extreme weather conditions. The self-adhering qualities of PAC-CLAD HT reduces labor costs and installation times while providing increased protection compared to that of typical felt roofing underlayments. This strong, skid-resistant high-tensile-strength rubberized asphalt membrane is available in either black or white.

-

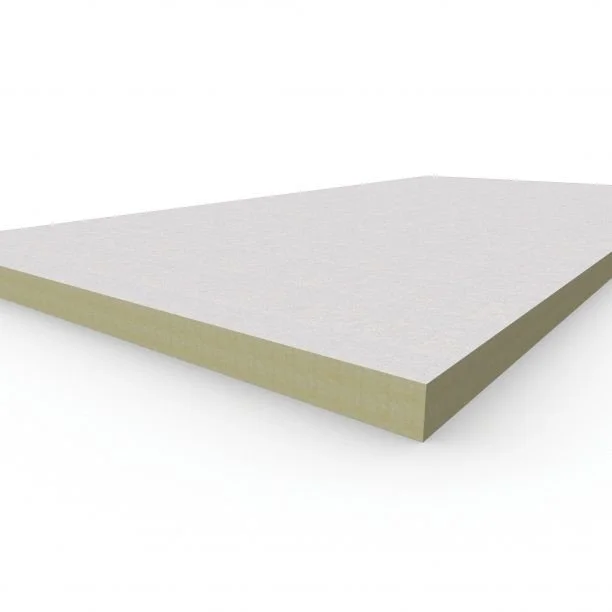

![PAC-850 Soffit]()

H-SHIELD

H-Shield is a rigid roof insulation panel composed of a closed cell polyisocyanurate foam core manufactured on-line to fiber reinforced facers on each side (GRF).

-

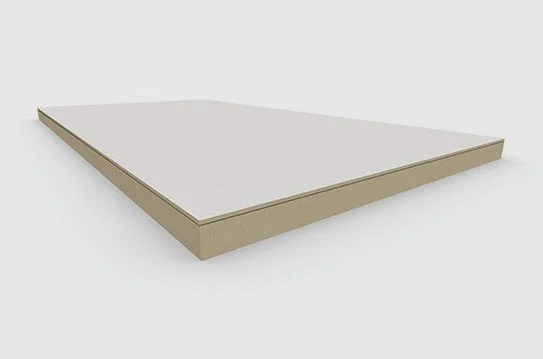

![Flush/Reveal Soffit]()

H-SHIELD NB

H-Shield NB is a rigid roof insulation composite panel composed of a closed-cell polyisocyanurate foam core manufactured on-line to a fiber reinforced facer on one side and either 7 ⁄16" or 5 ⁄8" oriented strand board (OSB) on the other. H-Shield NB can also be manufactured off-line bonded to 5 ⁄8" or 3 ⁄4" plywood.

-

![]()

H-SHIELD HD

H-Shield HD is a 1 ⁄2" thick high-density polyiso insulation panel specifically designed for use as a cover board. It is manufactured on-line to a premium performance coated glass facer on both sides (CGF). H-Shield HD delivers an R-value of 2.5 in its 1 ⁄2" profile; significantly higher than roof cover boards made with other materials such as wood fiber or gypsum.

-

![]()

H-SHIELD CG

H-Shield CG is a rigid roof insulation panel composed of a closed cell polyisocyanurate foam core manufactured on-line to a premium performance coated glass facer on both sides (CGF)

-

![]()

H-SHIELD HD COMPOSITE CG

H-Shield HD Composite CG is composed of two products, H-Shield HD - a 1⁄2" high-density polyiso cover board, manufactured on-line to H-Shield CG - a premium performance faced polyiso - creating a monolithic composite panel (CGF). This product is ideal for commercial roofing projects that require high thermal efficiency combined with maximum durability in both new construction and retrofit applications. R-value is optimized with a thinner profile than other insulations available on the market.

Ore Finishes

-

![]()

Enjoy the look of natural metal patinas that never change with PAC-CLAD Ore finishes from Petersen. Ore finishes provide designers with alternatives to expensive and unpredictable natural metals that will not tarnish, discolor or rust, making them an ideal option for clean, elegant metal architecture. A lineup of 16 Ore finishes ensures creative design flexibility and can deliver a finishing touch to any type of project. The PVDF Ore finishes are available on PAC-CLAD wall and roof panels, coil, and sheet in aluminum and steel. Ore finishes are not stocked, so consult PAC-CLAD representative to discuss warranty, lead time and related issues.

Wood Grain Finishes

-

![]()

When the performance of metal is required but the look of wood is desired, Petersen’s wood grain textures are ready to dazzle. Petersen’s PAC-CLAD wood grain patterns will convince the casual observer that metal is actually wood. A lineup of 16 wood grain patterns ensures creative design and flexibility and can deliver a finishing touch to any project. PAC-CLAD PVDF wood grain finishes combine the beauty of wood with the durability of metal. The patterns are nearly indistinguishable from actual wood, and they provide architects and designers with creative flexibility on highly functional surfaces. Wood grain finishes are available on all PAC-CLAD wall panels. Not all colors are stocked, so consult PAC-CLAD representative to discuss warranty, lead time and related issues.

NOTE: Colors listed as “Stocked” in the chart below are stocked in 24 gauge steel. All other colors and gauges are available but with extended lead times.

Anodized Aluminum

-

![]()

Anodized aluminum allows designers to inject creativity into any project. Petersen’s collection of anodized finishes includes the essentials: Clear, Dark Bronze and Black. For whatever signature look is desired, anodized aluminum can deliver beauty, long-lasting performance, light weight and corrosion resistance. The anodized finishes are highly resistant to ultraviolet light, and reflect years of research and investment in control of uniformity and appearance. The investment has resulted in the most consistent anodized finishes in the market.

NOTE: Finish warranty not available on anodized aluminum.

NOTE: More finishes are available but with longer lead time and subject to minimum quantities; consult rep for details.

Snow Retention

-

![]()

ColorGard® Snow Retention System

Petersen is stocking the patented ColorGard snow retention system. ColorGard is the only product available which will precisely match the color of any Petersen roof panel. ColorGard achieves this by utilizing a strip of the actual roof material, which is then mounted directly into ColorGard for a perfect match. This strip can be cut in the field or at Petersen’s factory. ColorGard utilizes the patented S-5! Clamp for its strength. The S-5! technology involves gripping the seam in such a way that there is no penetration to the panel material. S-5! utilizes round-point set screws for attachment which are specially made for the S-5! ColorGard or SnoFence™ snow retention system. These systems eliminate minimum temperature installation requirements and messy adhesives to apply. ColorGard can be installed at any temperature. For more information regarding ColorGard please contact your local Petersen representative.

Metal Fabrication

-

![PAC-750 Soffit]()

Coil and Flat Sheet

Coil and Flat Sheet Metal Fabrication – In addition to offering the industry’s widest selection of 70% PVDF (Kynar) finishes in steel and aluminum, Petersen also provides mill finish sheet and coil in a variety of gauges and widths. Anodizing-quality 5005-H34, as well as 3003-H14, is stocked in gauges .032 to .125 for all applications that require fabrication and post-finishing. With its state-of-the-art, cut-to-length and slitting equipment, Petersen can provide flat sheet and coil to exact specifications.

-

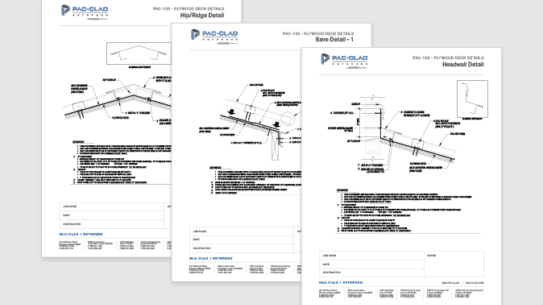

![PAC-850 Soffit]()

Flashing and Metal Roof Trim

Petersen maintains complete flashing fabrication capabilities in each of its plant locations to produce metal roof trims. Fabrication capabilities include press-breaking, shearing, welding and notching (notching available only from the Illinois factory). Each metal roof trim accessory is factory-formed in a gauge appropriate to the end-use application. Precisely matched color and finish quality is assured. For projects in which installer fabrication is preferred, flat sheet is available for immediate shipment. A complete set of flashing details for each panel profile is available at pac-clad.com, and includes detailed drawings for many flashing conditions. These flashing details should be followed, especially for any projects requiring a weathertightness warranty. Assistance with difficult or unusual flashing conditions also is available by contacting the local factory.

-

![Flush/Reveal Soffit]()

Custom Fabrication

Understanding that it’s all in the details is how Petersen provides custom fabrication that meets the customer’s requirements. With state-of-the-art technology and insightful expertise, Petersen ensures unmatched quality and service from coil to finished part to complete the most demanding projects. Petersen’s goal is simple: Provide precision-made parts to closely held tolerances to meet all of a customer’s expectations. With the most advanced CNC shearing and bending equipment combined with more than 50 years of industry experience, Petersen offers superior innovation and flexibility for producing a wide range of custom architectural components.